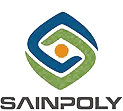

Venlo Polycarbonate Greenhouses – Premium Protective Growing Environments

Venlo greenhouses represent an advanced greenhouse structural design distinguished by their tall, sharply angled roofs that optimize interior air volume and ventilation. High-end Venlo greenhouses utilize robust aluminum frameworks integrated with insulating polycarbonate panels to create premium tailored growing environments for commercial horticulture.

Introducing Venlo Greenhouse Architecture

Venlo greenhouses were originally developed in the town of Venlo, Netherlands. Their characteristic feature is the distinctive roof shape which provides up to 35% greater interior headspace compared to traditional greenhouse designs. This additional overhead room enables substantially expanded vertical growing capacity for hanging or tall crops.

The aerodynamic angled roof shape and integrated vents also enhance passive ventilation driven by natural thermal convection. Hot air readily escapes through the roof vents while fresh air enters through lower side vents and screens in optimal convection airflow patterns aided by the sloped roof form. This passive ventilation capability provides efficient cooling without energy-intensive powered fans. The angled roof profile also readily sheds rain, snow loads and debris.

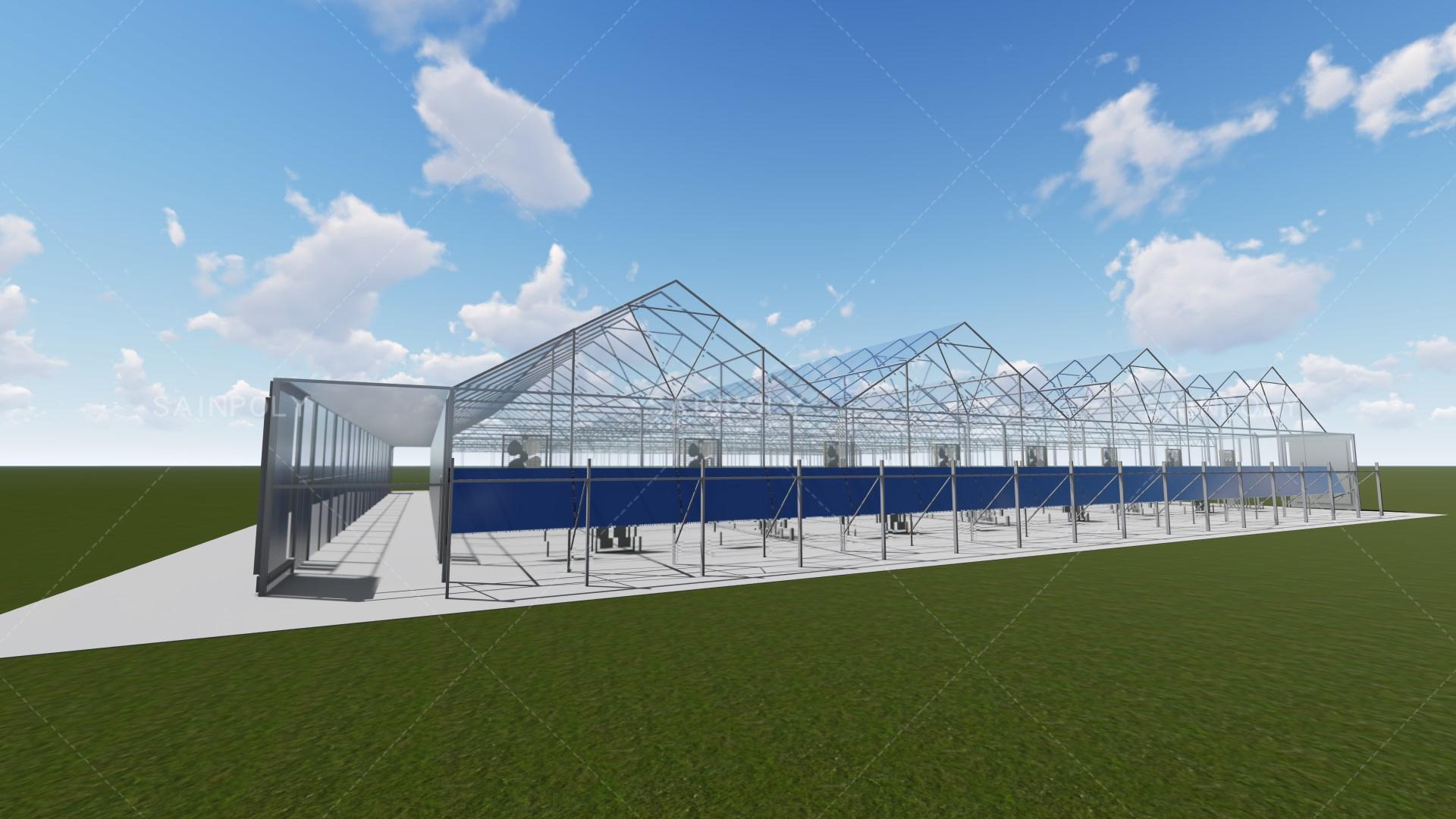

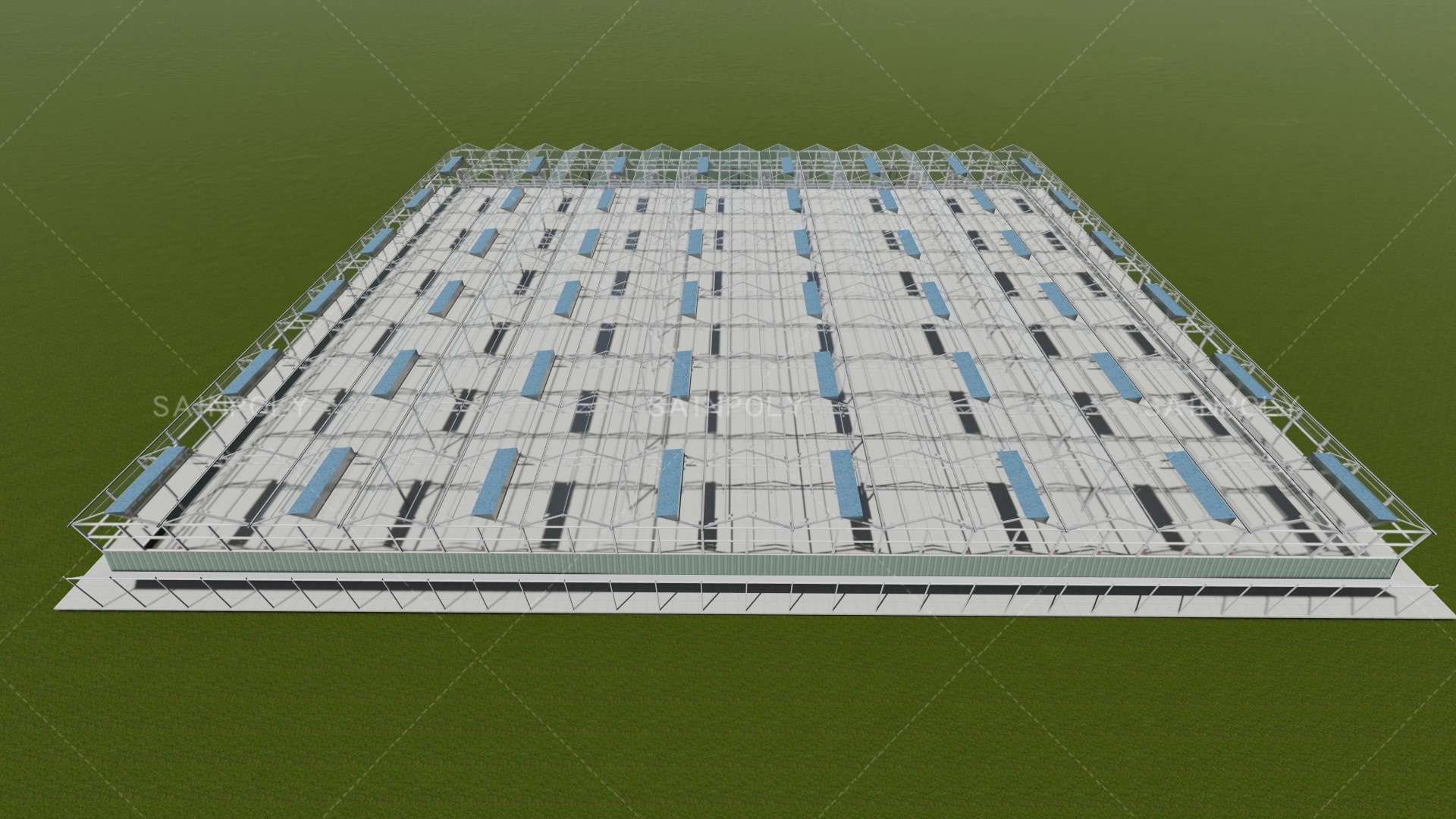

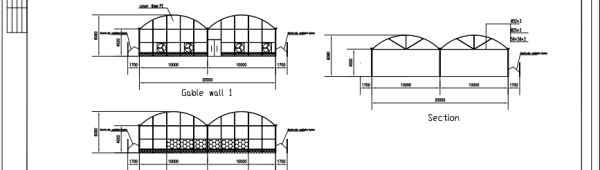

Venlo greenhouses utilize a modular bay construction typically consisting of repetitive arched trusses assembled into interconnected bays in span widths tailored for specific crops. This makes Venlo structures highly scalable for expansion. Properly engineered Venlo greenhouses can last for decades with proper maintenance.

Premium Venlo Greenhouse Components

Leading Venlo greenhouse manufacturers use robust, specialized materials to match the demanding structural requirements:

- Aluminum Frames – Extruded aluminum components provide exceptional structural strength while resisting corrosion and metal fatigue. Sections are precision-milled to interlock for added stability.

- Polycarbonate Panels – Multiwall polycarbonate sheets offer excellent insulation values to contain heat along with light diffusion properties ideal for plant growth and uniformity. The panels resist hailstorm impacts.

- Insulated Base Walls – Concrete or composite panel base walls prevent interior temperature losses while also providing critical anchoring stability.

- Advanced Coatings – Specialty UV-resistant coatings protect polycarbonate panels against solar degradation while maintaining transparency.

Integrated Venlo Greenhouse Functionality

Complete Venlo greenhouse packages incorporate automated systems for optimized growing:

- Ventilation Systems – Motorized ridge vents, eave vents, and side vents with screens balance temperatures and humidity levels.

- Supplemental LED Grow Lights – Interchangeable overhead lighting stimulates growth during low natural light conditions.

- Thermal Screens – Retractable energy curtains provide insulation at night while managing shading intensity during hot days.

- Fogging Systems – High pressure nozzles produce a fine mist to increase humidity during dry periods.

- Environmental Control Systems – Integrated sensors connected to central computers maintain optimal conditions by automatically adjusting equipment.

- Trellising and Training Systems – Suspended wires or rails allow climbing crops to be trained vertically to maximize space.

The Benefits for Protected Cultivation

Key advantages Venlo polycarbonate greenhouses provide growers:

- Expanded overhead space accommodates hanging crops with taller fruiting zones.

- Passive ventilation from the angled roof provides efficient, natural cooling driven by convection.

- Curved roof profile allows rain, snow and debris runoff while retaining heat in winter.

- Diffused light transmission through polycarbonate panels creates uniform growing conditions.

- Insulating multiwall panels keep interior temperatures consistent year-round.

- Modular interconnectable bays enable incremental greenhouse expansion over time.

- Robust materials withstand hailstorms and decades of intensive use.

Key Applications of Venlo Polycarbonate Greenhouses

The unique structural design of Venlo greenhouses makes them well-suited for a variety of commercial controlled environment agriculture applications needing expanded overhead space and passive ventilation capabilities. Some of the major uses of Venlo polycarbonate greenhouses include:

Tomato Production

The tall roof interior of Venlo greenhouses provides ample height for hanging tomato cultivation. Tomatoes can be grown on suspended strings or wires with a longer flowering zone, increasing yields. The passive ventilation also helps manage humidity and heat buildup from dense tomato foliage.

Cucumber Production

Like tomatoes, cucumbers thrive in the overhead trellising systems enabled by Venlo roofs. This vertical production method pairs well with the natural ventilation patterns in Venlo designs. The diffused light from polycarbonate glazing also reduces leaf scorching.

Pepper Production

Growing peppers in raised bags, nets or NFT channels along the greenhouse floor takes advantage of the overhead space for air circulation. The passive ventilation provides cooling to manage the heat from intense lighting optimized for fruiting peppers.

Vine Crop Production

Climbing vine crops like beans, peas, melons and squash can be trellised vertically using overhead wires or cordons in Venlo houses. This takes full benefit of the ample overhead room. Passive ventilation controls humidity and heat from the dense foliar canopies.

Nursery Stock Production

Young ornamental plants and tree seedlings thrive in the stable sheltered environment provided by Venlo polycarbonate greenhouses. Cooling ventilation and diffused light enable healthy growth. Overhead space permits vertical stacking of nursery plant trays.

Cut Flower Production

The consistent optimal conditions in Venlo greenhouses produce higher quality cut flowers with longer shelf lives. Increased disease protection also improves cut flower yields. Polycarbonate filtered light enhances color intensity.

Research Applications

Universities and research groups leverage Venlo houses to conduct controlled agriculture experiments. The passive ventilation and expanded height enable greater flexibility in trialing growth scenarios and technologies.

In summary, Venlo polycarbonate greenhouses are well-suited for many commercial high-value crop production applications, especially those needing ample overhead space for hanging vines or nursery stock along with integrated ventilation capabilities. The optimized structures maximize productivity.

For advanced protected cropping, Venlo polycarbonate greenhouses represent premium structures engineered for optimization, durability and longevity even in demanding climates. Their specialized passive ventilation designs and high-end materials create ideal tailored environments to maximize productivity.

Related Products

1

1 2

2 3

3