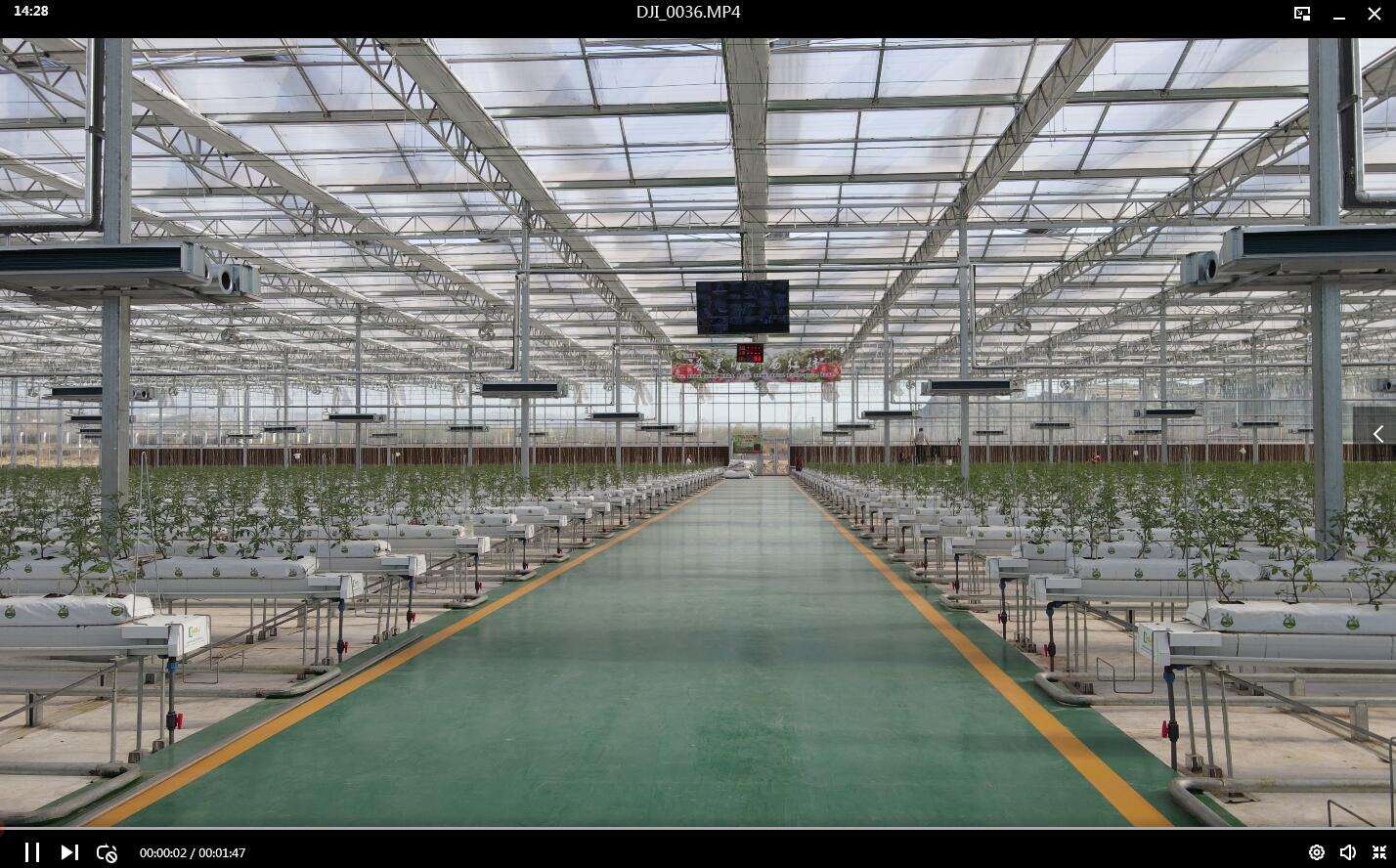

Success in commercial growing comes down to one objective: growing the highest-quality crops at the lowest overall cost. This goal is a driving factor behind almost every operation’s decision-making process, as they try to outperform competitors and create a growing space that’s as efficient as possible.

Although the idea is simple, bringing it to fruition can be a challenge for growers. Without the right tools in place, commercial crop production can be cost and labor-intensive, and operations aren’t able to achieve the quality of harvests they need to sustain long-term success.

Getting a reliable structure with the right growing equipment is a good start, but to truly optimize their greenhouse, commercial growers need to incorporate automation. An automated greenhouse allows them to streamline nearly every aspect of their production space and gain precision control over growing conditions.

Automation allows for precise control of environmental factors such as temperature, humidity, light levels, and irrigation. This optimal control creates an ideal growing environment, resulting in higher crop yields compared to traditional farming methods.

GROWER BOOSTING CROP GROWTH AND LIMITING COSTS THROUGH PRECISION CONTROL

IRRIGATION MANAGEMENTWater is a vital resource, and optimizing its usage is crucial for crop growth and cost reduction. Precision irrigation systems utilize sensors, weather data, and computer algorithms to deliver the right amount of water directly to plants’ roots when they need it most. This approach minimizes water wastage, improves water-use efficiency, and prevents overwatering or underwatering, leading to enhanced crop growth and reduced water costs. |

|

EFFICIENT LIGHTINGGreenhouse controllers often integrate with lighting systems to provide precise control over the duration and intensity of artificial lighting. This is particularly useful in regions with limited natural sunlight or for extending the photoperiod to promote plant growth during shorter daylight periods. |

|

TEMPERATURE CONTROLSince different crops perform better in various climates, growers can use automation to dial in their greenhouse environment as needed, with little time or effort. This can be accomplished in several ways, whether growers are heating in winter or trying to optimize cooling efforts amidst higher temperatures. During winter, growers can force their heating system to turn off once a set temperature point has been reached. With rising utility prices and a large-scale space to heat, this feature is more important than ever for commercial growers to conserve fuel and improve their bottom line. The same reality also pertains to growers in hotter climates, as running a cooling system all day can require substantial amounts of electricity. In fact, rather than relying solely on wet walls or ventilation, growers should complement their space with an automated shade system. Just like light deprivation kits, these can be deployed at pre-determined times to shield crops from the sun’s heat and help maintain interior temperatures. Having a high-quality shade system that’s programmed to operate on its own will require little labor, help reduce cooling costs and support healthy crop growth. automated greenhouse using shade system To start designing your own automated greenhouse, call or REQUEST A QUOTE today.

|

|